Drilling Procedure:

- Sonic Drilling up to the target depth

- Installation of Geo-loops

- Filling Gravel in Drill Pipe or Grouting

- Vibrating out Sonic Casing

Drill Strings for 100 m hole:TS 6-5/8" tool

- 6-5/8” Sonic Casing 3.0 m x 35 pcs

- 6-5/8” Sonic Casing 1.0 m x 5 pcs

- Sonic Ring Bit

Water well by SD-175 , SD-100 and SP-8000

Feedback from job sites:

“Drilling with 10-3/4”, 8-5/8” and 6-5/8” up to 165m was complete in 2 days.”

“Amazingly the amount of mud water is much smaller than the one by conventional drilling”

No water or less amount of water is only required by sonic drilling.

Drilling Procedure:

- Sonic Drilling up to 12 m x 10-3/4”for initial casing.

- Sonic Drilling up to 102 m x 8-5/8”

- Sonic Drilling up to 165 m x 6-5/8”

- Installation of PVC casing and screen inside Sonic Casing

- Removal of Sonic Casing & Filling Gravel

Drill Strings for 165 m hole:TS 6-5/8" tool

- 10-3/4” Sonic Casing 3.0 m x 4 pcs

- 8-5/8” Sonic Casing 3.0 m x 34 pcs

- 6-5/8” Sonic Casing 3.0 m x 55 pcs

- Sonic Ring Bit

Geotechnical & Sampling by SD-175 , SD-100 and SP-8000

Feedback from job sites:

What impresses most people is the ability of sonic rig to drill dry. Because it is so much less intrusive, particularly when talking about Dam remediation.

Drilling Procedure:

- Core Barrel Advancement with Sonic Rod

- Over Casing (Sonic Casing)

- Core Retrieval

- Repeat Process

Drill Strings: SDC 6 x 8 tool

- 4-1/2" Sonic Rod

- 6-1/4" Core Barrel and Core Bit

- 8-5/8" Sonic Casing and Bit

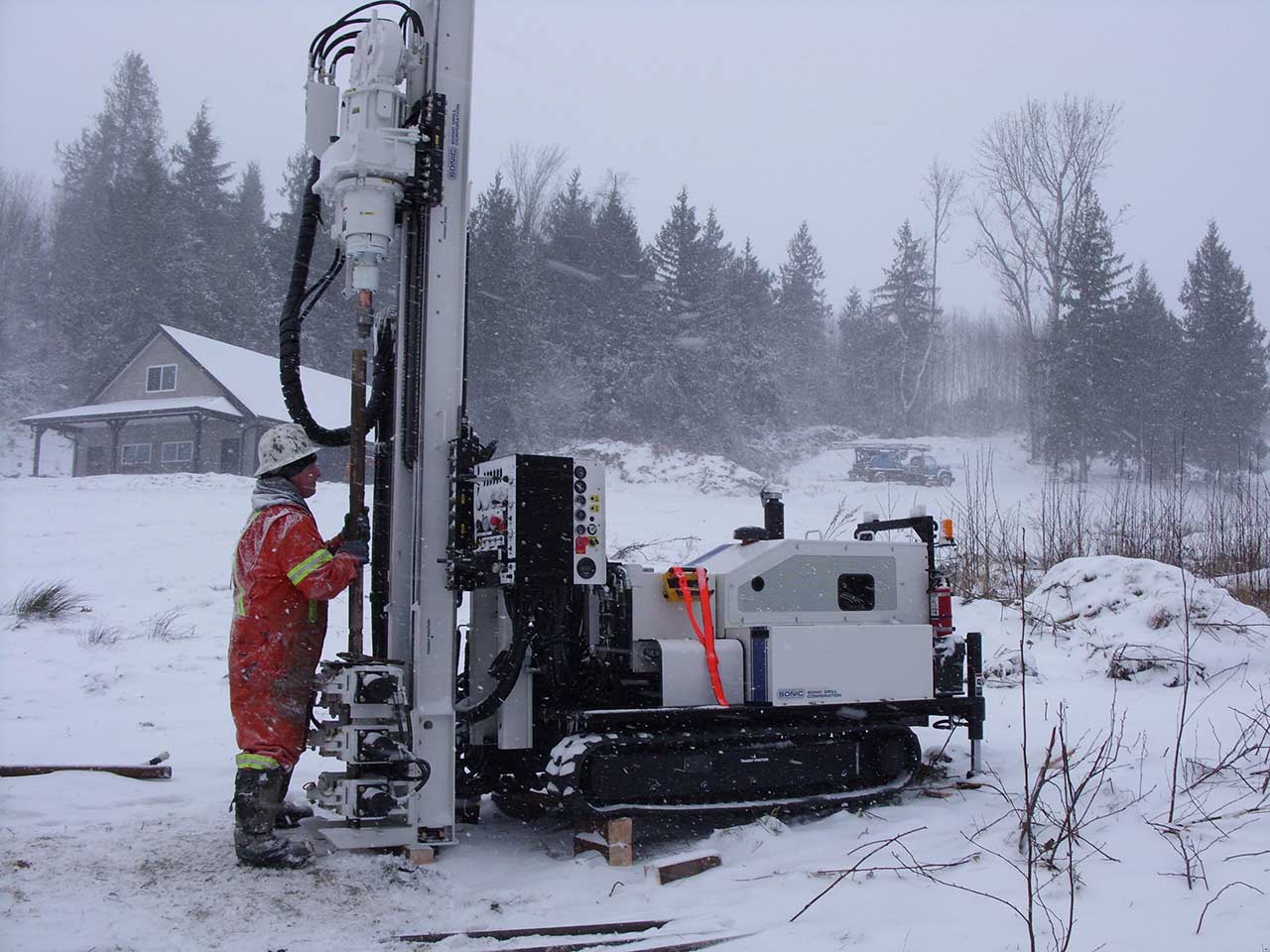

Environmental by EP-26N , SP-8000 , SD-100 and SD-175

Feedback from job sites:

“Frequency is much smoother and Noise is much quieter other similar drill rigs.

The client require TONE-PROBE for the further units.”

It is one of the standard drill rigs for Environmental investigation in Japan.

Drilling Procedure:

- Sampling for 1.0 m

- Retrieving Sampler with sample

- Set Casing for 1.0 m

- Sampling for the next 1.0 m

Drill Strings for 30 m hole:TP86 tool

- 2” Drill Pipe (MT50) 1.0 m x 30 pcs

- 86 Percussion Sampler 1.0 m x 2 pcs

- Percussion Bit

- 4” Casing (106.6) 1.0 m x 30 pcs

- Casing Shoe

Grout & Anchor Hole by SD-100

Feedback from job sites:

“Much quieter than Hydraulic Drifter.

It can work in residential areas.”

“The capability to drill very straight hole is very helpful for the grout hole project which requires the accuracy of hole positions.”

SD-100 (33K) can drill Horizontally and up to upward 20°

Drilling Procedure:

- Sonic Drilling up to the target depth

- Installation of PVC pipe

- Grouting

Drill Strings for 60 m hole:TS 4-1/2" tool

- 4-1/2” Sonic Casing 3.0 m x 20 pcs

- 4-1/2” Sonic Casing 1.0 m x 5 pcs

- 5” Sonic Ring Bit (Body and Ring Bit)

- 5” Sonic Ring Bit

Piling by SD-175 and SD-100

Feedback from job sites:

To be updated shortly

Drilling Procedure:

- To be updated shortly

Drill Strings

- To be updated shortly

Drilling capability varies according to many factors. The introduced drilling capability and customers feedbacks on the website are only examples and these are not guaranteed.